-

Posts

2212 -

Joined

Content Type

Profiles

Forums

Store

Blogs

Events

Downloads

Supra Articles

Gallery

Everything posted by jaymdee

-

Help needed please. Front crank pulley won’t budge

jaymdee replied to jaymdee's topic in mkiv Technical

Update. With help from a mate who builds motorbike race engines we helicoiled the stripped thread (was only one in the end) and with a little measured encouragement with a blow torch (not too much and applied in several stages) we’ve got the pulley off using the puller. Hopefully no detrimental effect to crank and oil seals etc. You can see rust on the crank which I’ll need to sort out before the new pulley goes back on, so probably why it was such a pig to remove the old one. Jon -

Am trying to change the cambelt among other things and the pulley nut is off but the pulley won’t pull off the crank. We’ve tried using a puller and all that’s happened is the threads inside one of the puller bolt holes have stripped. Any suggestions before I look into whether I can tap a hellicoil in there? on another forum someone suggested getting behind the pulley with a nut on the puller bolts. Is that possible, as it looks like the plastic housing and aux belt tensioner are in the way. thanks Jon

-

Urgently needed. Car in garage and caliper seized. Anyone got a serviceable one which could be available for quick delivery? Stock UK big brakes, 2 piston type Thanks Jon

-

Thanks guys. Yeah. I got some degreaser on it and will see if I can locate source of any leak. cheers

-

New alternator arrived and today was first chance to try and fit it. can anyone tell me whether the oily pipe which seems to come from the bottom of the water pump needs to connect anywhere, as it’s just hanging there? Is it an overflow pipe? cheers

-

Great news. Thanks Ric

-

Alternator is out. Connector was fiddly and needed the flat screwdriver trick. 10mm bolt needed to be loosened off and the alternator then rotates free of the cooler pipes. I have noticed white gunk/chalk in the connectors on the car and the alternator. Is this dielectric grease? Am thinking of getting an SRD 170amp standard. Anyone got any experience? Does it come with the right size pulley and uses the same size serpentine belt? My belt looks worn so going to buy a new one.

-

Thanks guys. I managed to get a bit of video on my phone and I think Scooter is right. Looks like a bracket holding the oil cooler pipes which hopefully drop down clear when I undo the nut. Thanks for the tip on the connector. Unfortunately jacking it up and getting underneath is not an easy option where it is currently parked, so hopefully can do it from above. Will have another attempt when it’s next dry.

-

Hi. After much reading on this, I find myself 2 hours into a supposed 30 min job (some forums have even suggested 20 minutes) and still don’t have the alternator out of the car. the fan shroud doesn’t seem to be as described in other posts and is an all in one unit with a secondary mini fan integrated into it and what looks like a load of 10mm nuts at the bottom holding it in place. I have managed to remove the viscous fan (after removing the top radiator hose) and I hope that will be sufficient. next issue is I can’t for the life of me find the lower bolt/nut by feeling with my fingers and it seems there are additional oil cooler pipes which I’ve not seen mentioned in any other thread I’ve read. I’m also stumped as to how to remove the plastic electrical connector on the back of the alternator. I’m concerned that I may break it and there’s no obvious clip or method to remove it. I’ve removed the 12mm nut and wiring loom attachment clip etc. any suggestions most welcome??? thanks Jon

-

Cheers people. Still not managed to get this sorted yet but some good tips. Hi Chris. Good to hear from you. Hope you guys are doing well.

-

Driving home tonight and suddenly had the battery warning light, engine oil, engine heat (?) and hazard warning lights all come on. Stopped and restarted and still the same so drove home 5 mins figuring it’s the alternator. Battery down to 11.8 volts. Should have tested it before I turned it off. have seen posts suggesting to check earths (where, how?) before buying a new alternator. Getting a lift to work tomorrow but will try a few tests on Friday. So where’s best for an alternator for TT auto? cheers Jon

-

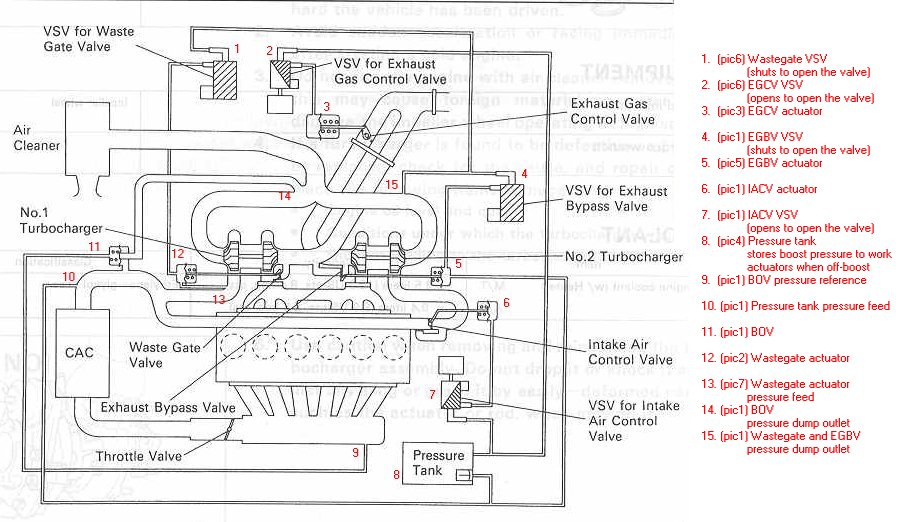

I ‘think’ it can be done by someone with very small hands without removing anything, but I removed all intake pipes, the small bore black metal turbo pipe work, VSVs and actuators the IACV, turbo heat shield and loosened T1 (front turbo) to get some pipes off. Basically everything except the turbos. And it was still difficult. I used a bic biro to stretch new silicon hoses over and then dropped onto the 2 little hard pipes poking up and then squeezed the biro out. As I said, I reckon it took me about 30 hours going slow and methodically, plus I electrically tested all the VSVs. To be honest was very surprised I managed it and it worked. I did find a few small holes in the 2 hoses which connect to/from the pressure tank.

-

HaHa, was about to post a link to my thread from last year and then clicked on Scooters link, thinking it would be the Ian C turbo thread and it was mine. Yes. Replacing the two small vacuum hoses down the back of the engine which run to/from the pressure tank totally cured the problem. Took me about 30 hours to remove, clean, test all VSVs etc and refit, but definitely worth it. (I’m very slow, lol!!)

-

Spotted 4pm 1st March, at petrol station on roundabout on the A12 north of Brentwood.

-

I'd be interested too. They look really smart.

-

Resolved. See here http://www.mkivsupra.net/vbb/showthread.php?354424-Resolved-Lost-boost-and-no-second-turbo&p=4301027#post4301027

-

All back together and tested and the difference is amazing. Replacing the collapsed link hoses means it can breathe so much better and with new pressure tank hoses (and I also replaced some of the 25 year old 6mm hoses) the transition from vacuum to positive boost on T1 is seamless. Am seeing 0.8 bar boost at 3k rpm on T1 and no more issues with T2 coming on line and am seeing 1bar boost rising to a max of 1.2 at high rpm. Hopefully the silicon hoses will be ok, but well chuffed that for now at least it seems to have been worth the scraped knuckles and cuts and bruises...

-

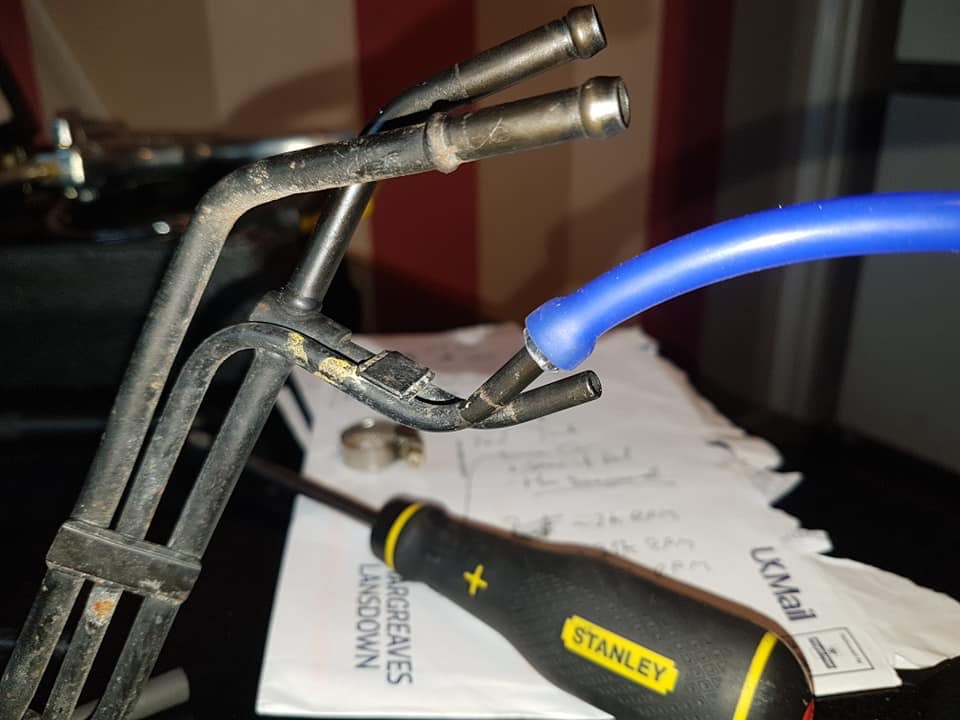

Investigating anywhere boost can disappear and I’ve taken the reed valve on top of the IACV apart (which I guess allows the prespool from T2 to get to the Y pipe?) and here is a picture. There is a slight gap between the metal plates and the housing which I assume the boost from T1 keeps shut. Cheers Scooter. I bought some thick sidewall silicon for the 2 pressure tank pipes. Absolute bastard to get back on. In the end I inserted a biro which was big enough to fit over the hard pipes on the car, cut it off and was able to push the pipes on. To be honest whilst silicon probably isn’t best, I don’t think I can get anything else on unless I remove the turbos... .

-

Further update. Have removed the black metal Spaghetti pipes and removed the small bore hoses to / from the pressure tank and the return hose which feeds the IACV and EGCV has a hole in it. Awaiting some replacement silicon hose which I hope will work ok. Not an easy job to get to these hoses. Taken about 10 hours in total to remove everything (total novice, lol) and test the vsvs so I hope it’s worth it! A few pictures

-

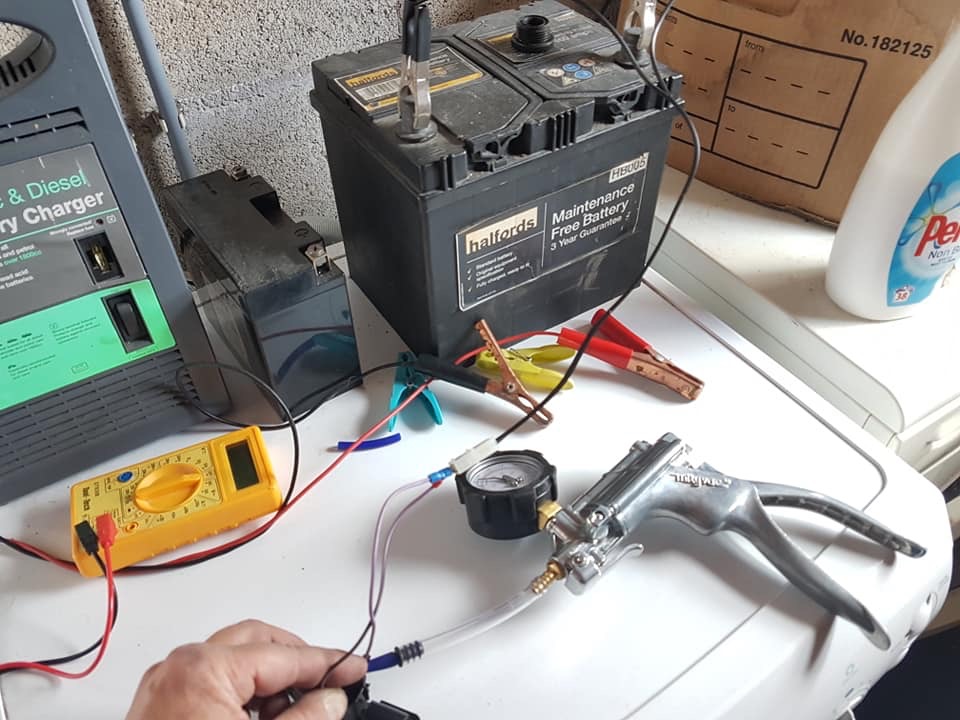

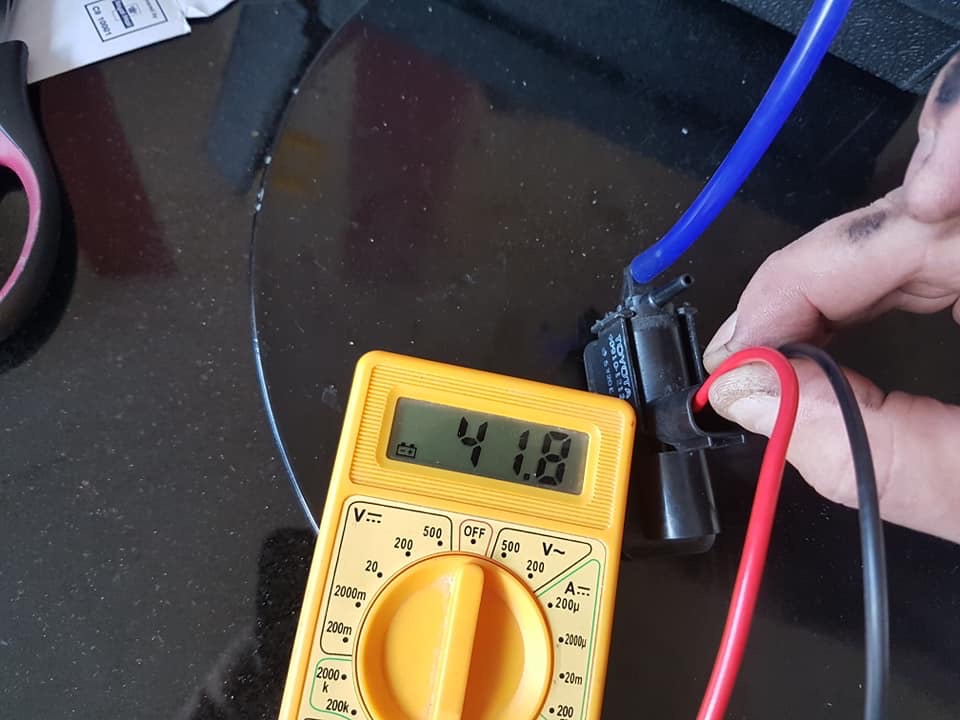

Update. Since yesterday I have begun removing bits from the intake pipework and tested the following. All vsv's show correct resistance and operate as they should with 12v applied. Turbo link hoses have collapsed so ordered new ones IACV observed. Closed with no pressure and then opens with pressure applied to the actuator. HKS bov tested to 15psi and not leaking Wastegate actuator tested and starts to open at about 15psi. Rod is connected to the external fitting on the exhaust housing (Can't really check whether the internal flap is working correctly, but I can hear 'something' slam shut when pressure is removed, so I assume it's that). Next steps, once new link hoses arrived is to replace old vacuum pipes and try and get to the pressure tank hoses. The tank seems to hold 10psi and operate the IACV and EGVC actuators but loses pressure after 10 minutes or so and the actuators withdraw. Have heard of people saying theirs holds pressure over night so could be a problem. Also want to test the intercooler for leaks somehow.

-

Something I don’t understand is how the pressure supplied to the pressure tank seems to get T’d off and feed the EBV. If the EBV VSV is normally open, then wouldn’t the pressure simply run through the EBV VSV and back into the air side of T2? Also, I can’t for the life of me find where this T is in the actual system. (Ie the T at the bottom of the diagram under the pressure tank)

-

Cheers. Just read that and also looked at the Wilbo666 website and saw the actuator on the egbv has 2 pipes on it, similar to the wastegate, hence why I couldn’t get it to hold pressure and operate the actuator and valve. Am going to spend time next week doing the resistance checks on the vsvs and removing the 2 accordion link pipes and checking the operation of the IACV Thanks. These posts and the links threads have really helped! Jon

-

Thanks Scooter. Lots of good info on testing vsvs there and I’ll do some more testing in TTC. I’ll be honest I can’t quite work out the operation of the EGBV from looking at the vacuum pipe work. I tried pressurising the pipe which I think goes from the vsv to the actuator and couldn’t get it to hold any pressure, although I’m not convinced I was able to get a good seal on it. Although if this wasn’t working I think I should still see decent boost from T1 under 3500rpm even if the sequential system wasn’t working properly. As another thought, if the wastegate was stuck open I guess this would prevent T1 from spooling. Managed to test the wastegate actuator and can see the rod operating, but can’t see whether it’s connected to anything or not as it’s buried down in the engine bay I think I’ll also check the big accordion link pipes Cheers Jon

-

Following on from this technical thread, http://www.mkivsupra.net/vbb/showthread.php?354287-Failed-pressure-tank-and-or-hoses... Spent a few hours testing pressure tank and associated system and actuators with a mityvac and I think that it’s holding pressure ok. Looking at one of IanC’s posts on the sequential system faults I wonder if the IACV is stuck open hence not getting anything much on T1 and only getting something at high rpm when there is enough pressure in the system to operate the EGRV. Anyone else experienced this? Also thought the HKS bov might have failed and just dumping the boost. Thanks Jon

-

Thanks Mike. Yes we put shims in and no more squealing. Cheers