-

Posts

2660 -

Joined

-

Days Won

55

Content Type

Profiles

Forums

Store

Blogs

Events

Downloads

Supra Articles

Gallery

Everything posted by Mike2JZ

-

Are you hitting some sort of boost cut? Accelerating in 6th gear is going to cause high load, could cause your boost to overshoot depending on your boost controller setup.

-

Checked all my saved resources, can't find any Toyota published data for those measurements. I've never bothered measuring those diameter on a stock rod, wouldn't surprise me if most were a bit out of wack after 25 years. Stock components with big power is always a bit of a roll of the dice. One thing I will say is to upgrade the stock rod bolts as they can snap before the rod bends in some. Edit: might be worth measure stretch on stock rod bolts. see if any variances on the bolts matches what you are seeing on the rod itself.

-

Updated with sold items.

-

It was used on my friends car whilst it was still an NA-T with an auto trans, and needed a piggyback that would allow for fuel & ignition with boost, but still retained stock ECU for auto trans control. Since then he's gone manual and put a standalone, so no longer needed.

-

Hi, For anyone looking to use a MKIII R154, I have some specific MKIV conversion parts up for sale. - R154 OEM Flywheel (used) £90 - R154 to JZ Bellhousing £150 - R154 Shifter Extension 4.25 for perfect MKIV fitment - £150 - R154 to MKIV Small Case Diff Propshaft - £250 - MKIII R154 Cube Short Shifter with shifter straightened - £75 - W58 Speed Sensor (can be used on R154) - £120 Prices do not include postage. Thanks

-

Hi, Bought this off some guy on eBay a while back. Guy tried to hide some damages to exhaust with exhaust wrap, and I was going to get a welder to fix it. But now decided to go with 4'' exhaust system for more flow, so no longer need this. Looks like the exhaust had been on a low car at some stage at it's life as midpipe has a few scrapes on it, but nothing critical. The backbox however looks like it has taken one too many hits as it has a large hole in it, and some idiot has tried to fix another hole on backbox using steel on titanium. So the backbox either needs removing, fixing or replacing with a striaght pipe (someone please do this) On the plus side, this thing is silly light. Feels like 2KG or less. £150 + post

-

Hi, Emanage ultimate in good working condition. Removed from NA-T. Includes Greddy 3 Bar map sensor (needed for NA-T guys) Can be used for NA-T or TT's. £350 inc post

-

If you already have an A02A in the car, and you want to put a A02B in the car then it will feel exactly the same in terms of ratio. The only difference will be when the back end steps out, it will feel more stable as A02B uses torsion LSD.

-

Yes you can

-

Yes you will need a timing light. Something like this is what you will need https://www.amazon.co.uk/Draper-52616-Xenon-Timing-Light/dp/B0001K9V3Q/ref=sr_1_3?keywords=timing+light&qid=1563483507&s=gateway&sr=8-3 To set ignition timing you will need to have the car up to temperature. Then in the engine bay find your diagnostic port, and using a bit of wire bridge E1 & TE1. This will lock your ECU's ignition timing. You can confirm this has been successful as your engine management light will be flashing constantly when ignition is on/car is running. Now is a good time to go to your distributor and locate the 12mm nut that holds it to the head. You need to loosen this nut so you can twist your distributor left/right. Just don't remove the nut completely, just enough so you can move the dizzy. So with the engine running, connect your timing light to HT lead #1 and point your timing gun down at the crank pulley (try and avoid getting your timing light wires caught in the viscous fan) https://imgur.com/a/ZLMuTcn With your gun active and pointing at crank pulley, you should see a small white mark on the crank pulley appearing. You need to reference this mark in relation to the timing marks on the lower cambelt timing cover. Now whilst you are flashing your timing light at crank pulley, twist the distributor until you align the mark on crank pulley with 10 degrees BTDC. https://imgur.com/bf00744f-6cfa-4067-9e41-6b31a906f987 Once you are happy you are at 10degrees BTDC, tighten the nut on the distributor. Check one last time with your gun that you are still at 10 and the job is done.

-

What kind of measurements do you get for oil clearance on the rod bearings if you use plastigauge? Not doubting your measuring skills, but just to sanity check. 0.07-0.09mm oil clearance as you have calculated is beyond the max for rod bearings. Should be between 0.023 to 0.041mm range for a STD bearing set

-

Yeah thats a good 30 minute job there taking off the inlet. Most NA's I see suffer from this issue, its rather common. So probably that.

-

Easiest way to tell is to take the cam covers off and check the rubber gaskets. If they feel brittle and like plastic then usually the cause for oil to leak through. SRD/Whifbitz etc will stock these.

-

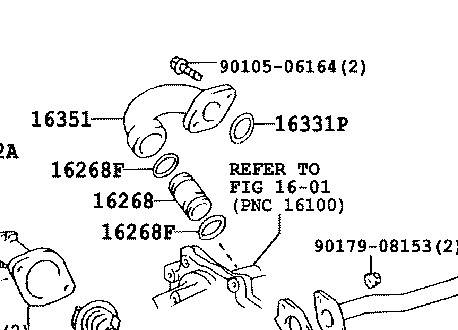

You can take those part numbers and go to your local toyota. They can order them in for you Generic O-rings may work, only one way to find out

-

If new rear discs have been installed, then make sure your handbrake shoes have been adjusted accordingly. Sometimes the extra meat on the new discs can make contact with the handbrake shoe. I have seen this before with a car going into reverse, so shoe may need loosening slightly? If your rear brakes have no squeal shims then they may be correct and it just needs a set of those. You can see on this page, the part numbers for the shims in case you need to get some http://www.japan-parts.eu/toyota/jp/1995/supra/jza80-alfvz/4_291130_006_/powertrain-chassis/4707_rear-disc-brake-caliper-dust-cover/2#47748F

-

The pipe that is leaking is more than likely from one of the two rubber o-rings that hold the water neck to the bypass tube. To fix this you will need to drain the coolant from your car. Remove the distributor, then you can access the waterneck. Waterneck is only held on with two m6 bolts. Once those are off you will need to remove the bypass tube. Depending on how corroded it is, this could be as easy as pulling it out, or getting a set of molegrips on it and trying to rotate/pull until it comes free. Assembly will be the reverse of this, using your new O-rings. Be sure to grease the o-rings slightly on install, as if they have no grease they can tear on install, causing a leak. Part #'s of parts you need: Water Outlet O-Ring: 96761-24028 Water Bypass Tube O-Rings (2): 96761-24022

-

Hi welcome to the forum. To be honest sounds like you have most of the major components needed to convert the NA5 to a TT6 without much aggro. I'd agree that you should give building it a go. First any modifications required to the harness going from a w58 to a v161? are the plugs the same? can i just plug in it and it will work Assuming you are using a TT6 engine loom then there are no modifications required. The loom will have the correct plugs to go straight into the V160. If you are using an Auto Twin turbo loom, then you will need to modify a few wires to get the loom to work with a V160. Luckily you already have the connectors you need on your NA5 loom, so you could take them from that. You will need to play with a total of 7 wires, so nothing crazy. I believe there is an issue with the tachometer unless you get a tt6 one, which i did , however is there also any issues with the speedometertach The NA tach signal is a "low" signal, whilst the TT tach signal is "high". You can bypass a resistor on the NA tach to get it to read "high" signals when you convert to TT. Otherwise you can take a TT6 tacho and will work with no modifications. The biggest issue with using a NA speedo with a TT6 drivetrain is that the clock will be calibrated for a different differential final drive. So your speedo will read higher or lower then the speed you are actually doing. TT6 speedo would be the best plug and play solution, but even these can be innacurate when you run larger tyres than what the factory configured the speedo for. Luckily, I see on your list you will be using a Link ECU. I always run the gearbox speed signal through the Link ECU, before outputting to the speedo cluster. This allows you to tune the signal for whatever gearbox/tyre size/diff final drive you may be rolling with. So this allows you to run a NA speedo with whatever you like. I have an igniter from a twin turbo but if i decide to delete it with different coils does that effect the tacho? And if so what is the solution? On the stock ECU setup deleting the coils is possible, however you have to keep a number of igniter circuits happy otherwise you get put in a limp mode with lots of error codes. Depending on what coils you are running, this ranges from moderately difficult to absolute ballach. Luckily if you plan to run the Link the Tacho signal is generated by the ECU as it reads the Crank/Cam signals before outputting to Tacho cluster, rather than relying on an igniter to give the signal. This makes coil swaps a walk in the park. In one of the stickys it said you need the throttle control ecu but ive read that you dont need it unless you want traction control which i dont. Is this true and if i dont plug it in do i get any warning lights? On a stock ecu setup you can run without the throttle control ECU, but this disables the TRAC system and will have a few warning lights unless you pull the bulbs out. Aside from the lights, the car will technically run fine. Again, if you go to a Link ECU this all becomes redundant and you can throw away your TRAC ecu with no fears. Ive seen posts where people say you need the relay for the fuel pump and other posts that say you dont, just want to know if there is any modifications to the fuel pump required , i have a 255 spare if required buy more interested in the wiring side. no hassle if i have to wire in a fuel pump switch. On a stock ECU, maybe at BPU level there is no need for a 12v relay conversion as the fuel pump ECU is adequate. However when going for more power, the fuel pump ECU can sometimes be hard to interface with using a standalone ECU. Or in some cases just can't deliver the same amount of juice that a relay connected directly to battery can. I wouldnt worry unless you go down the standalone route. In which case, depending how adventurous you are feeling with wiring and tuning you could try to get stock fuel pump ecu to work. Personally I always use a relay thats hooked directly battery. I like to get the flow out of my pumps using 13.5v or higher, unlike the stock pump ecu that can only output 12v. If anyone has done this swap , any information would be greatly appreciated. I read many auto to manual swaps and na to turbo but cant find information on this particular swap. If ive missed anything or any parts please let me know. 1. Take out 2JZGE & gearbox in one go with wiring looms attached. Throw in garbage (jk keep the shortblock) 2. Drop your old diff & driveshafts. Install TT6 replacements. Don't forget to install second diff bush whilst everything is out. 3. Fit V160 & GTE wiring loom to 2JZGTE engine. Do the reverse and install into car. Marvel how everything just fits and is plug and play. 4. Figure out installing stuff like intercooler, exhaust etc. 5. Plug your link into stock wiring loom. Wire in a Link map sensor. Connect to ECU, load 2JZGTE base map from Link. Start car and take to tuners. Thats obviously quite high level, but process is as simple as that if you have all the right bits. If you have any more questions regarding specifics of the swap process then I can try to respond.

-

Generally speaking a mild 264 cam will not put as much strain on your stock valvetrain, but it isn't advisable to be running more than 7500 on stock springs for extended periods. Considering most 264's will help your mid range power rather than pure top end, it is acceptable to run them without changing anything. That said, you can get 264 cams with lift as high as 9.5mm or more. This will put you on the border of being an interference engine and the aggressive lift will put more strain on stock springs. In this situation, new springs and retainers are advisable, especially if you want to increase RPM limit. If you want to run stock springs, I'd shoot for a cam that has a lift somewhere between 8.6-9.0mm to play it safe. Technically you could run a set of 272's on stock springs. The problem you will get is that the extra load on the springs will expose any fatigue they might have faced after 20+ years. This can increase your chance of experiencing valve float at higher rpm's which will net you performance loses and possibly leading to valve/piston contact depending on how you intend on abusing the motor. Given that most 272's are going to be borderline or full interference, better to not take the risk and upgrade springs at the same time. The argument of staggered cams verses non staggered is a thread on it's own. But usually a non staggered setup is more than adequate for most people out there. Edit: I'd personally only bother with 272 cams if you have a built bottom end, large turbo and are expecting to rev to a minimum of 8k. Otherwise 264 will be competitive on performance gains until that point. 272's do sound the bollock on idle though, so I understand if thats the main motivation

-

Was this on an emanage?

-

Take inspection plates on gearbox off and peer inside. Can tell from pressure plate if its oem setup. Checking flywheel is more difficult, easiest with gearbox off

-

Could just be me, but I avoid bosch plugs on 2J's. Always had issues with them, I use NGK on everything and always works

-

Sounds like dual mass flywheel, unless you have an uprated clutch

-

Trigger 2 settings look incorrect. Change cam pulse to crank pulse. Your trigger arming voltages are a bit shit too. Try these https://imgur.com/UrxmIrA Dwell settings look ok, but you can get away with higher dwell ms using a distributor then you can with a ignition coil. Unless you are going mad with the boost then should be fine as is. Be sure to check your base timing with a timing light. Unlike a TT using crank sensor, the distributor can turn slightly which will offset your ignition timing, so very important to check base timing and calibrate correctly. Whilst running the engine, use the Link to log Trig1 errors, Percentage FCut, Percentage ICut. These are some of the main variables that will indicate if your ECU is causing or detecting a misfire.