-

Posts

10276 -

Joined

Content Type

Profiles

Forums

Store

Blogs

Events

Downloads

Supra Articles

Gallery

Everything posted by David P

-

Hello Rich, Welcome to the club. The exhaust manifold is an Autobahn88, which takes up more space than the stock item, there are some snaps of it in my garage and albums. It will be tight, but it will go in. The bonnet will need a bulge of about 1" to clear, but will get to that later. The configuration will be the same as the Jag installation, but using a 72mm throttle body taken from a Lexus 400 and mounted before the s/c and routing the bypass hose into the charge cooler. Initially, I will leave the compression stock, the NA-T boys in the U.S. are running up to 14psi on pump fuel, and I will have the water/meth injection controlled by the AEM ECU, I am curious to see how far a stock N/A engine will go. The transmission I am planning to hybridise should be good for 500ft lbs, so that will be a limiting factor. Using the 6.78" ATI crank pulley, here are the M112 cubic inch per revolution (1835cc) supercharger boost/pulley size figures; 4.50” = 11.9 psi (0.82 bar) = dynamic compression 15.8:1 - 664 cfm (18,802 lpm) @ ambient temp - engine 6,800rpm s/c 10,245rpm 4.40" = 12.5 psi (0.86 bar) = dynamic compression 16.2:1 - 679 cfm (19,227 lpm) @ ambient temp - engine 6,800rpm s/c 10,478rpm 4.25" = 13.5 psi (0.93 bar) = dynamic compression 16.8:1 - 703 cfm (19,907 lpm) @ ambient temp - engine 6,800rpm s/c 10,848rpm 4.00” = 15.3 psi (1.05 bar) = dynamic compression 17.9:1 - 747 cfm (21,152 lpm) @ ambient temp - engine 6,800rpm s/c 11,526rpm 3.80” = 16.9 psi (1.16 bar) = dynamic compression 18.8:1 - 786 cfm (22,257 lpm) @ ambient temp - engine 6,800rpm s/c 12,132rpm The engine I have for mock ups is minus a power steering pump, I will need one of these to aline the supercharger bracketry. Does anyone have a dead one going cheap? I have been preparing the distribution knuckle ready to weld to the cooler. After many hours of grinding, it is now gasket matched, gas flowed and where it can be seen have removed the casting marks from the outside too.

-

You ask a question, I provide the answer complete with pic and part number. You ignore it, take the wrong advice and give thanks! You will do very well on here. "Use a 4Runner distributer cap, 19101-65040"

-

Thanks for that snippet, I will check the next time I am tinkering down there. Yet I have a wideband O2 sensor and the gauge reads 14.5 to 14.7 in closed loop so would suspect that this indicates they are functioning correctly. (Excuse the thread hijack)

-

Nic, I have seen reference to fitting new O2 sensors on many occasions, and the soak them in lemon juice overnight remedy. Bearing in mind the cost of these items, can they be tested to learn if they require changing before spending what might be just for the sake of it?

-

I have a matrix in A1 condition.

-

Cheers for the heads up, will go take a look at the build, don't know how I missed that.

-

Thanks for the compliment gazzi. I have been tinkering with my N/A for the last 12 months. This has not been a buy it and bolt it on excercise, few have bothered to develop the N/A and consequently, both information and 'effective' bolt on goodies are rare. Many of the components used have been designed, built, redesigned and rebuilt by myself, then tested and retested by the seat of my pants until developed/evolved into modifications that give more power. Photographs and details of these developments are posted in 'my garage' and albums, where there is extensive information recorded. I am expecting the final components required to complete the build to arrive in the next few days, so in a few short weeks it will be ready for the day of reckoning on the rollers. I am keener than anyone to see my labours reduced to a number.

-

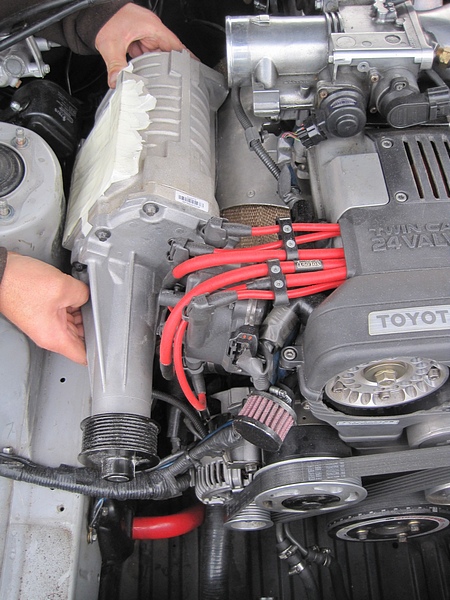

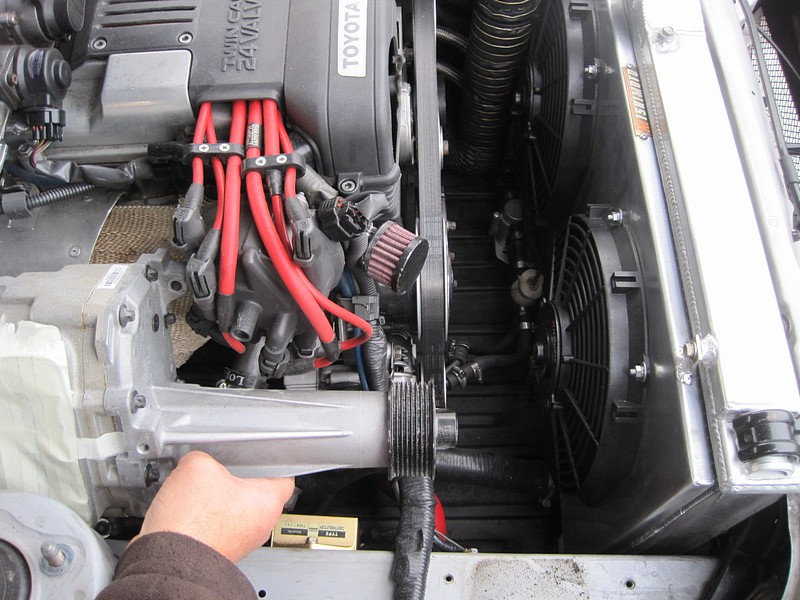

Good news re. tyres. Have fun. Here's a video of an uncompleted s/c conversion. This is an M112 and stock headers, with the Autobahn88 I do not have room to fit it just there.

-

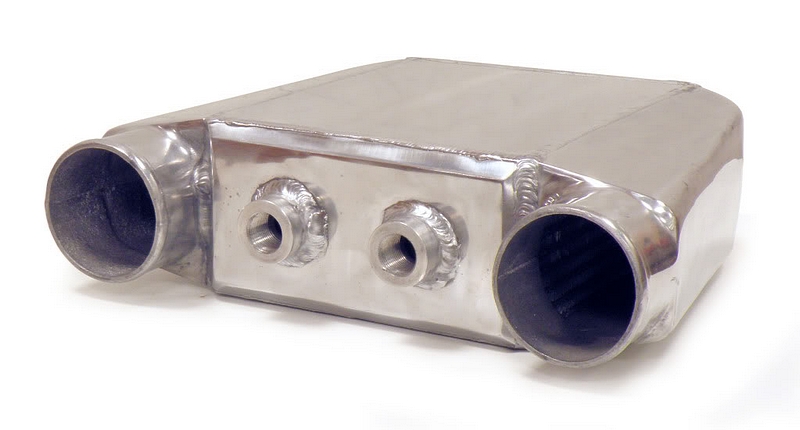

My thoughts exactly. I have an active spoiler which I like and want to keep, and a cold air induction feed so there is no room for FMIC pipework, or a SMIC. This cooler will re-fab a treat and look amazing.

-

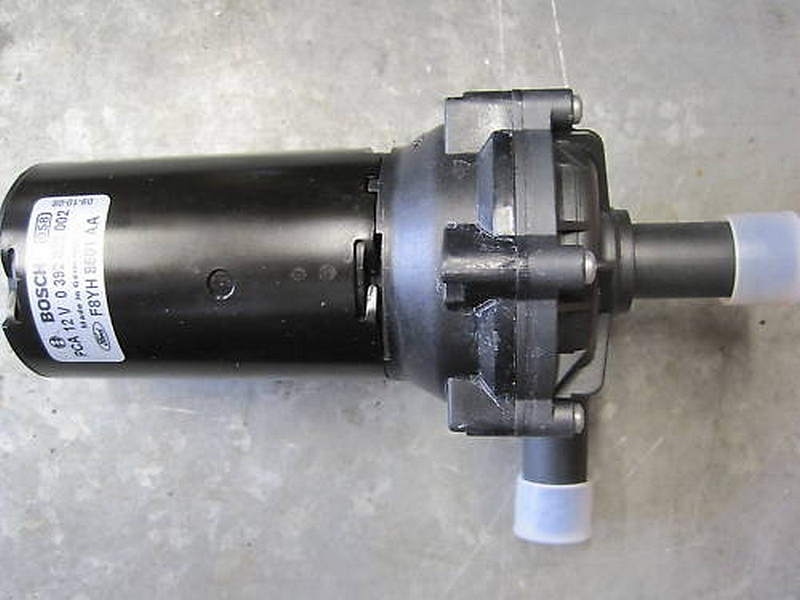

I have managed to get a U.K. spec fuel pump from a club member. It will make a nice change to do something simple. OE Denso 300lph, plug and play. And found on ebay a new Bosch 1,200 lph pump for the charge cooler circuit. I will fit the water pump and charge cooler pre rads when I install the HHO system and water/meth injection. They are all going in front of the rad, so it makes sense to do them all together.

-

Tinkered some more today. As I suspected, there is not room for the rear dogs leg mounting bracket. Mr Eaton uses exceedingly strong 'aluminum'. Two brave hours with a steady hand and a disc cutter later.... I will trim it to the line another day, my hands were getting numb from the vibrations. It will be tight, but it will go in with some 'easing' here and there. There would be more room with stock headers, but not going back. There is a limit to how far I can progress with the mounting brackets until the offset pulley arrives. The remainder of the day was spent with a wild goose chase to a mechanical band saw at my pals farm to cut the charge cooler up, but it would not fit into the machine. It looks like I will be discing all day on sunday too.

-

Short, sharp and positive. Maybe the forum needs a smiley for that.

-

The Eaton number refers to the cubic inches displacement per revolution, M112 = 112 cu in (1835cc) M90 = 90 cu in etc. Not concerned to support the snout, if it is good enough for Jaguar, then it will be good enough for me. It is the mounting of the s/c that I will focus on getting rock solid. This afternoon I will be having an in car mock up and measure up, I think will need to cut off the Jag rear leg on the charger because it protrudes too far towards the exhaust manifold. There are plenty of other options to get a good mounting.

-

Plug changes will be easier than with stock N/A, it only takes 5 mins to remove the cooler for access. The stock T.T. A343E trans is good for 500ftlb+. I will be hybridising this with an N/A trans using the N/A valve body and cable line pressure control, allowing me to use the Suprastick ECU. I could change the prop and diff to T.T. but want to keep my one piece alloy prop and slip yoke connection. So the tricky bit will be to machine the N/A output shaft to fit the T.T. clutch packs to the N/A splined tail shaft.

-

It's an M112, this one was for the 4.2, but believe it's the same size charger on both of those engines.

-

I will obviously run cooler plugs, and outlined my transmission plans in first post. "I am planning to build an N/A T.T. auto hybrid, good for 500ftlbs + and Suprastick compatible, so I can keep my 'flappy paddle' gear change".

-

Look at pic 6. After the cooler, the charged air enters a plenum before spliting into the runners, in fact, the whole charge cooler will be the plenum as it is the same width and open to the pre runner plenum.

-

Click the link in my signature and take a browse around my garage and albums, you will find answers to many of your questions there.

-

I have every confidence with the s/c conversion, it will be the transmission that will be the challenge.

-

Give me a chance, I only started today. I am going to use the N/A throttle body, and mount it pre charger, not interested to have sneezing noises. Bob had his hands full with the charger, maybe I should have asked him to hold the t/b with his teeth.

-

I am waiting for components to complete the N/A build. They should be here in a week or two I hope, then I can get it finished and on the rollers. Then we will all know the magic number. Whilst waiting, tinkering with this.

-

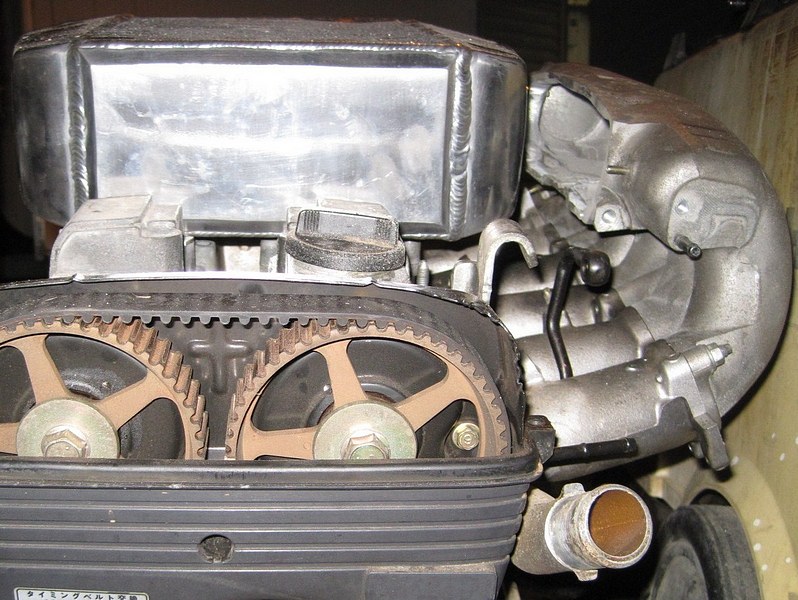

* (Full up-to date pics, specs and vids here.) I have started to tinker with an Eaton M112 Supra supercharger conversion. The plan is to mount a Jaguar XKR 4.2L V8 Eaton M112 supercharger over the Autobahn88 exhaust headers and feed it through a water-to-air charge-cooler fitted on top of the engine. I am also building an N/A A340E - T.T. A343E manualised automatic transmission hybrid, good for 500ftlbs + and Suprastick compatible, so I can keep my 'flappy paddle' gear change. The car has an active spoiler that I want to keep, which means no room for FMIC pipework, and the front will be 'busy' with 2 HHO generators, a water/meth system and 8 HID ballasts. I also have a cold air induction feed that I want to keep, which means no space for a SMIC. The distributor will be awkward to work around, but to change to coil on plug would raise the height of the cooler by a couple of inches and I don't want a 'Mad Max' bonnet. Here is the charge cooler I have found to redesign for the job, it is rated at 600bhp+ and I will also have water/meth injection, so plenty of induction cooling there will be. This is a charge cooler pre rad from a Jag X300, I have 2 of these, they are the perfect size to fit. They each cooled 326bhp, so a combined 752 will keep induction cool and deter detonation in this high compression build. The port matched Autobahn88 headers have 10 layers of wrap and can be held by hand even after a good thrashing. I have bought an N/A engine to use as a jig, and to have as a spare just in case the one I have now fails. Here is a snap of the first mock-up. The rockers have now been cut away to make room for the charge cooler to fit into the divot, and the 6 branch knuckle has been opened up ready to weld directly to the charge cooler. There is more work to be done cleaning up and reworking the casting. I have finished re-working a set of runners, and they will go on as part of the N/A build as soon as I can organise a phenolic gasket, and then will be in situ ready for the supercharger conversion. Here's a snap of the cooler in the cut out rockers ready to be marked for the side to be cut off and mate up to the knuckle. Birds eye view ready for the cut and shunt.

-

From the album: Supracharger Project

-

Heard this one today and thought of Chris, "It's the first time anyone has had their finger in Diana's ring since Dodi"