-

Posts

10276 -

Joined

Content Type

Profiles

Forums

Store

Blogs

Events

Downloads

Supra Articles

Gallery

Everything posted by David P

-

N/A & T.T. seats are the same flavour But if your Supra is LHD, then the passenger will get the drivers electric seat, and the driver would get the passengers non electric version. Wrapping those up would be a PITA, that's why I stated buyer collects. I will let you enquire re. shipping cost, and the packaging materials would cost about a tenner each. Please keep all coms in open forum, for the information of other members.

-

The engine is running sweetly @ 14.7:1 in trundle mode, but way too rich at WOT, so try and lean out the air fuel ratio, I have reduced the fuel pressure from 43.5 to 36.5psi. Whilst at AFR, I had the car run on the rollers, yet it looks as though the £50 spent has only confirmed that I would need to spend 10x that much to have the AEM installed and set up to release the gains. Here are the print outs that show that even with the reduced fuel pressure, it is still managing to find way too much of it.

-

SOLD Black leather pre facelift seats. Leather good, bolsters good, electrics good, runners good. As good a pair as can be found. Drivers seat is without belt clip. (The drivers seat does not have a mark, it is dust on the lens) Buyer collects from Kettering. £300 Unsold until payment received.

-

B+ to Fp held up for the grand tour to AFR, SRD and then Sheerness on the way back, with very positive results. I dropped off the skirts and spats for Jagman. (Adam) Dude (John) was very helpful with my project, and from amongst his collection of Supra treasures he routled out a T.T. auto bell housing, flex plate complete with shims and bolts and a dead power steering pump. Thank you very much. Then on to SRD to pick up Jamies' seats where Lee was very helpful too, he had a routle around and found me a T.T. torque converter. Thank you very much. Then on to Sheerness to pick up a T.T. auto trans from Miguel. Thank you very much too. That leaves just the N/A trans to collect, and then I can begin to hybridise the two.

-

No fault codes. Apparently, the T.T. pump runs at 2 different voltages, low power for cruise, and high power when suppling demand for boost, the T.T. pump ECU controls this. The N/A pump ECU won't have this arrangement and the U.K. pump also draws more watts. There was I thinking it was a simple job. I hope the pump is happy to run at full tilt for a few hours, because i'm going on a trip tomorrow.

-

Shane, Thanks for the offer, but if the ECU is cooked, it was the U.K. pump that fried it! I don't want to fry yours too. Tomorrow I will phone Keron, if anyone knows, he will. At a guess, I may need to fit a T.T. fuel pump ECU.

-

As a workaround I have pinned out B+ & Fp in the diagnostic port, but this arrangement is; ignition on, pump on. I have discovered that the T.T. has a fuel pump ECU that increases the power to the fuel pump when on boost, but not sure of the wiring for the N/A. I will investigate more when it is not dark and raining.

-

I have upgraded the N/A fuel pump for a U.K. spec version. I was expecting this to be a 'plug & play' job, it plugged in everywhere O.K. but does not want to play! The pump operates whilst the starter is turning, the engine starts and the pump turns off? Does anyone know the answer to this Supra electrickery conundrum?

-

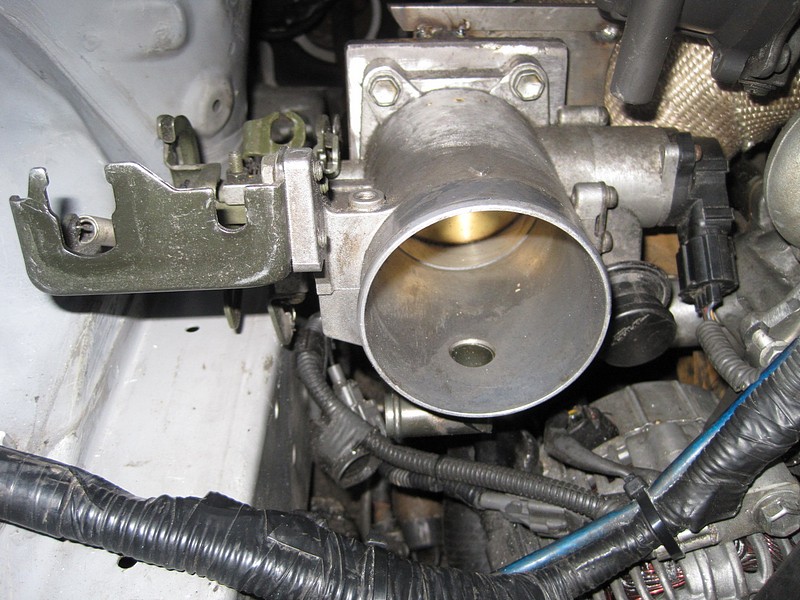

Whilst waiting arrival of the stainless steel bends required to complete the induction, I have terminated both ends of the t.b. hot water pipe. The N/A t.b. will need to come off for the next trial fitting and this pipe is not used, so it might as well be gone. I have also changed the fuel pump for a U.K. spec version, I was expecting this to be a 'plug & play' job, it plugged in everywhere O.K. but does not want to play! The pump operates whilst the starter is turning, the engine starts and the pump turns off? Does anyone know the answer to this Supra electrickery conundrum?

-

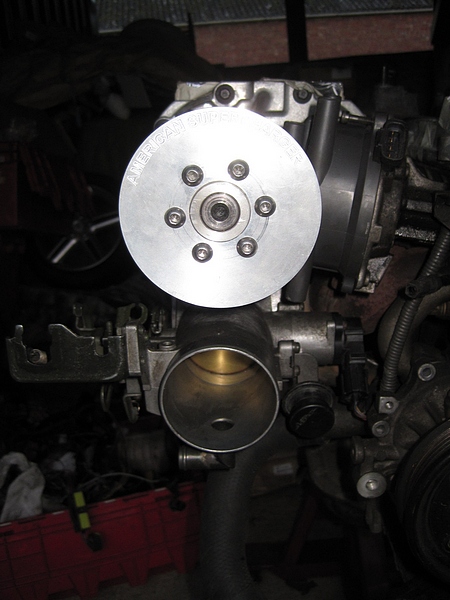

That was "simples" £80 + VAT + £4 P&P made using 6082-T6 and dispatched 5 days after receiving pattern. Found this too. 6082-T6 Brinell n/a, Vickers 95 YS: 260 MPa, 37700 psi 6061-T6 Brinell 95, Vickers 107 YS: 276 MPa, 40000 psi 6351-T6 Brinell 95, Vickers 107 YS: 283 MPa, 41000 psi 6151-T6 Brinell 100,Vickers 112 YS: 295 MPa, 42800 psi 6009-T6 Brinell 91, Vickers 102 YS: 320 MPa, 46400 psi 6070-T6 Brinell 120,Vickers 137 YS: 352 MPa, 51000 psi 6066-T6 Brinell 120,Vickers 137 YS: 359 MPa, 52000 psi 6013-T651 n/a, Vickers 149 YS: 359 MPa(min), 52100 psi(min) 6033 T6 Brinell 120, n/a YS: 393 MPa, 57000 psi 6069-T6 n/a, n/a YS: 441 MPa, 64000 psi

-

Thanks for the lead Barney. I will give them a call.

-

I have discovered that 6061 - T6 is the grade of aluminium required to make the 4.4" pulley, and have found it available in billets up to 120mm diameter if I buy a container load from China. But yet to find a source for a little piece, does anyone know where I could get an off cut?

-

I have spoken with the local engineer about making a 4.4" pulley, but he doesn't know where to get a billet of 'aircraft quality' aluminium without the aircraft price tab? I have also asked the American manufacturer of the 3.8" pulley, but they claim not to be able to get a piece large enough? What is the correct term for the quality of aluminium required to make this pulley? Yet more importantly, does anyone know where I can get a piece of this elusive alloy?

-

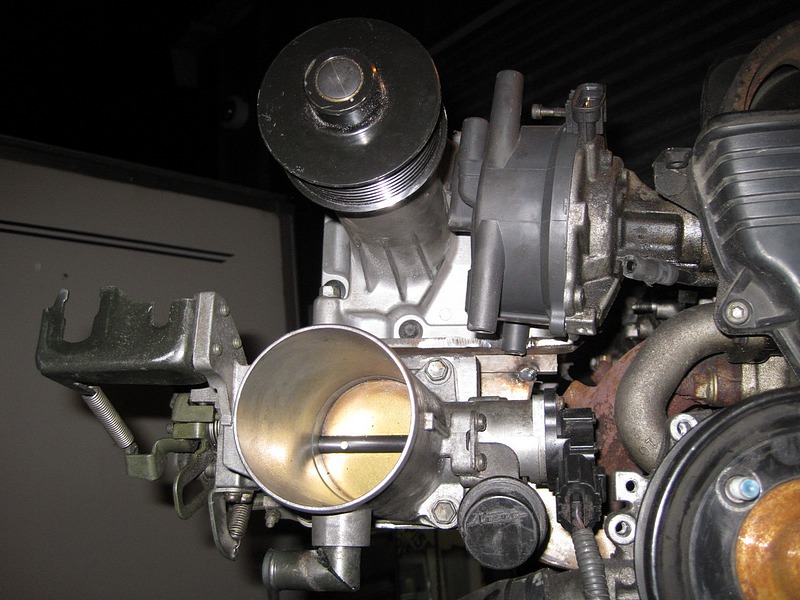

After all the tales of woe I have read about changing the jag s.c. pulley, I was dreading this job. I set it up on the hydraulic press on a pair of well fitting 'half moons' and it 'cracked' and eased off a treat, then simply pressed the new quick change centre on. The lesser of the 2 offsets possible with this pulley lines up nicely and spaces the inside s.c. mounting nut just clear of the distributor. I will have to set it up and tack the bracket in situ on the car, because there isn't a power steering pump/pulley on the jig to work to. This pulley is a 3.8", which is too small for the job, but will be fine for aligning the charger and completing the bracket whilst I have a 4.4" made. Have also been for a routle around the scrapyard looking for some 4mm alloy plate to build the charge cooler, I only found enough for half the job, but was amused by it's origin.

-

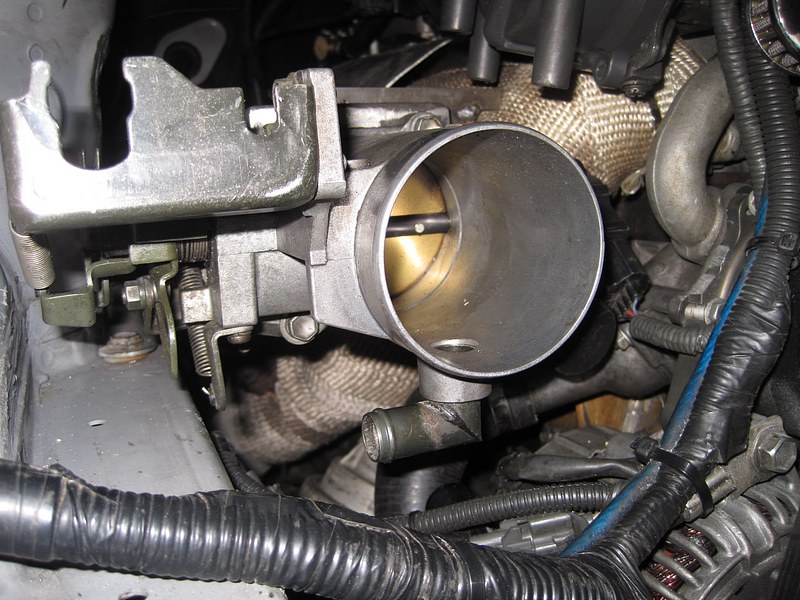

I have pruned off a mounting lug from the water pump, extended the O2 sensor wire and tidied up the loom to maximise available space. The trial fitting of the jig built t.b. mounting, ended up with taking it off and spotting it back on again, it is tighter in there than a good saturday night. I even needed to trim the plastic loop off the T.P.S. connector and shorten the connector body to make it on and offable. I will measure the engine movement under load, yet I am reasonably sure that it will not foul, if it does I will tweak the spring hanger across a little to clear. I have decided that to use vacuum hose was not one of my better ideas, so will complete the induction in stainless pipe, it is half the price of alloy too.

-

I have been wishing that I hadn't found that little square of 8mm steel that was almost the right size for the t.b. flange, it is as hard as flint. The front leg is now at the finished height and plane with the top of the block, with the t.b. mounted and first section of induction tacked into place. I will have a test fit on the car tomorrow to see if it needs any tweaking before welding.

-

They look good, and a design that is uncomplicated to keep looking good too. 5 spokers are my favourites on a Supra

-

My projects have become tangled up. The original intent was to see how much power and economy could be squeezed from an N/A, then whilst enjoying these gains, to continue on and tinker about with a supercharger conversion. Other than induction prior to the runners, all components are common, and is a logical route to follow. However, it took so long for the hydrogen generators to arrive, to fill in the time I began tinkering with the supercharger conversion. The 17 weeks delayed arrival of the HHO kit coincided with the recent ice age, so it now makes more sense to tinker about making components inside, compared to lying outside under the car freezing my nuts off! Consequently, by the time the weather has improved enough to sensibly get back under the car, the supercharger conversion will be sitting in the shed waiting to go on. Should the Supra pack up, I would have to get out and get under, but I tinker for pleasure not purgatory. As much as I would like to complete my normally aspirated aspirations, it would be dickthippery to fund a comprehensive rolling road session to install and set up the AEM ECU, Aquamist 2C water/meth injection and the HHO system, then to go home, bolt on the supercharger and go back and pay for it to be done all over again! Consequently, I have chosen to compromise. The engine is running very nicely on the stock ECU, with the exception of being too rich when over 4k rpm in open loop. I have decided to back off the fuel pressure to reign this in as best I can, to try and lean out the AFR to 13:1 at 6.5k rpm and let the ECU learn to sort itself out in closed loop. Then to take it for a run on some rollers and see what it has got. This measured run will be minus the gas flowed runners, phenolic gasket, AEM, water/meth injection and the HHO system. Without these final gadgets and components the numbers achieved will be smaller, yet the results should be more informative to N/A owners, who most likely wouldn’t go to the extent of installing these items.

-

All panels straight, paintwork is good and wean as a clistle underneath too

-

If you are planning to 'tinker' with it after buying, Shane has one up for sale for half that price. That would give you a head start with your budget.

-

There might be a few more get there if it was added to the club calendar.

-

Hello Adam, Thanks for the input and positive comment. As can be seen in the pics, whether it likes it or not, the t.b. will go where it fits in this scrapyard jigsaw puzzle. The pipework between t.b. and s.c. has an i.d. 5mm larger than the t.b. and the flexi vacuum hose forms a nice 'flowing' bend. Pre t.b. will be an 80 to 102mm 90o silicone elbow, directly to a K&N filter in a cold air fed box similar to my present set up. Bearing in mind the limits of the T.T. auto transmission, I think there will be more than sufficient breath from this arrangement to have it worried enough. Next job is to raise the top of the front leg by 11mm to achieve the finished height, and to weld on the t.b. flange. Having different manifolds on the engine and jig is a PITA, I shall be pleased when the sky hook guessmeasurey is over and the bracketry complete. Dave, Thanks for your 'vote of confidence'. Yet all l I have achieved so far, is to reduce perfectly good components into a 3D jigsaw puzzle, and set myself on fire. I am looking forwards to nailing them into place.

-

That bracket looks a right dogs breakfast, and no strut ring fitted either!

-

I spent this afternoon fabricating the induction plumbing and flanges. It turned out that the steel I had found was not mild, but tempered. It cut easily enough with a 1mm disc so hadn't noticed, yet boring the holes took ages. The blade was old yet I was getting suspiscious, then when working it with a grinding disc it became obvious, especially when I set myself on fire with the 'cold sparks'! Looking on the bright side, I can be confident that the flanges won't twist.

-

Kevin, Cheers for the encouragement, there's a long way to go yet. Shane, I am confident with all aspects of the design, except maybe asking too much of a 6 rib belt? Yet should that be so, it won't be difficult to upgrade to 8 rib pulleys. Regarding your cast pipe; I still have a hankering to include that, but not sure where? Next time I call to check out your coffee making skills, I will take a better look at it. Maybe I can cut out the 'pretty piece' and have it welded onto the front of the charge cooler?